Technologies

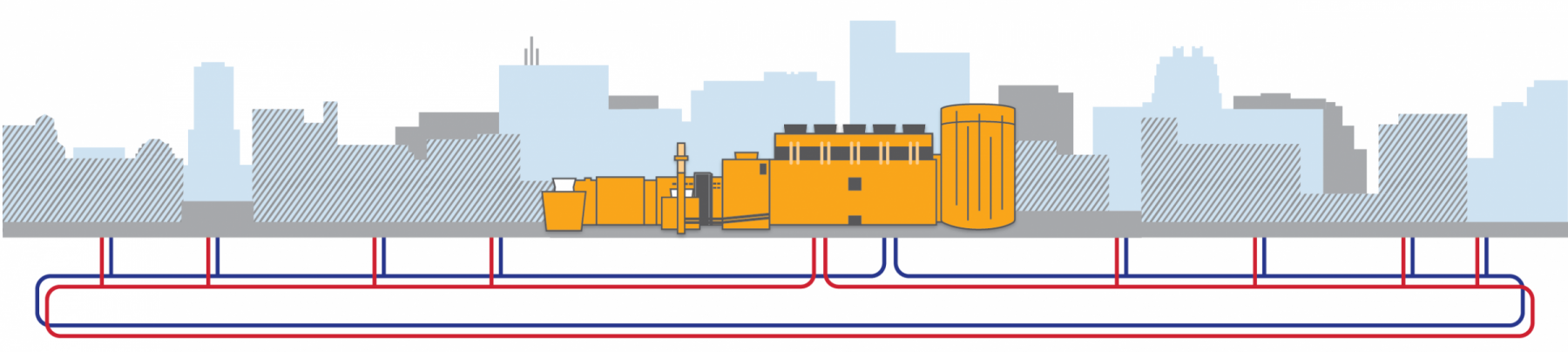

TECO’s Central Plant (Paul G. Bell, Jr. Energy Plant) and South Main Plant produce chilled water and steam. TECO pipes that energy underground to customer buildings for air conditioning, space heating, dehumidification, humidification, sterilization, kitchen and laundry processes, and research and domestic hot water use. Customers don't need their own boilers or chillers since TECO’s chilled-water and steam system does that work for them.

TECO’s Central Plant began operation in 1969 and has expanded over the decades. Its largest-ever expansion – a $377 million project – began in 2007 and was completed in 2011. It made TECO the largest district cooling system in North America, transforming its energy operations. The project included

- a 48 MW combined heat and power (CHP) unit, which can meet 100% of TECO’s electricity needs;

- an 8.8 million-gallon chilled-water thermal energy storage tank, the tallest thermal energy tank in the U.S.;

- a new chiller building with 32,000 tons installed capacity, expandable to 80,000 tons;

- a 138 kV electric substation upgrade;

- an operations support facility with state-of-the-art control room; and

- a distribution system expansion that included a new utility bridge over Brays Bayou to reach additional areas on campus.

Combined heat and power. TECO’s CHP unit is 72% efficient, more than twice as efficient as a conventional power plant. It is the driving force behind TECO’s environmental accomplishments and cost savings. CHP’s high efficiency allowed TECO to rebate customers a total of $55.2 million between 2011 and 2020. CHP enables TECO to produce power and thermal energy from a single fuel source. Standard power plants use just one-third of the fuel they burn to produce electricity. Two-thirds of the fuel used is rejected or “wasted” up the smokestack. By capturing the waste heat to produce cooling or heating, efficiencies go up and emissions go down. TECO now has 90% fewer NOx emissions and 48% fewer CO2 and total greenhouse gas emissions annually compared to a conventional electric generation and heat-only system.

Thermal energy storage. TECO charges its thermal energy storage tank at night when electricity rates are lower and discharges the tank during the day to save on electricity costs. It helps TECO save an average of 6% annually on energy consumption compared to running the equivalent chillers during the day.

Piping system. TECO’s piping distribution system has 35+ miles (7.7 trench miles) of piping ranging in size from 6 to 60 inches in diameter. It serves the Main, Mid and South campuses at the Texas Medical Center, spanning the Brays Bayou via a utility bridge added during its major expansion. Dedicated, experienced TECO personnel are on-site full-time inspecting all piping construction projects daily. A third party inspects and x-rays every weld, and geotech engineers are on-site full time during backfilling to ensure compaction specs are met.

Check out images of TECO’s facilities below.